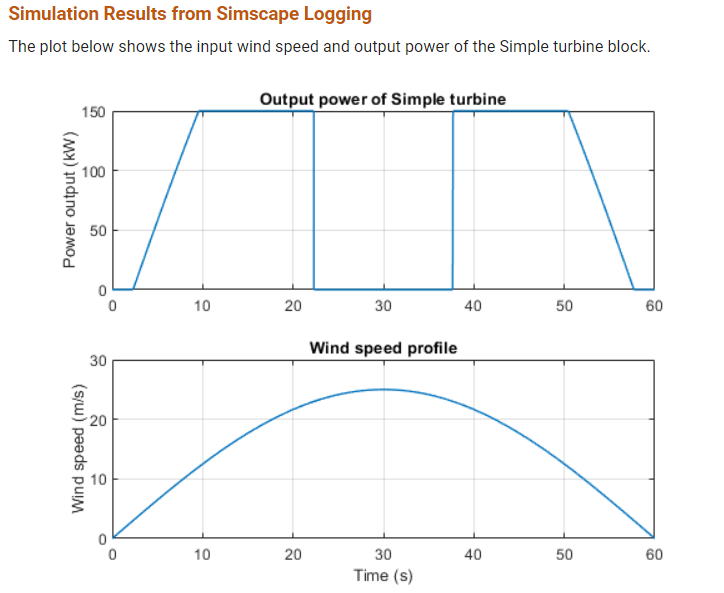

1, Fan model

function power = simpleTurbine( windSpeed, ratedOutputPower, cutInSpeed, ratedOutputSpeed, cutOutSpeed ) %#codegen

%Simple Turbine

% This function implements a simple power versus wind speed characteristic This function realizes simple power and wind speed characteristics

% to represent a wind turbine.

% Given an input of wind speed, m/s, the function outputs turbine power, W.Given input wind speed m/s,This function outputs turbine power W.

% The parameters must meet the following requirement:

% Cut-in speed < Rated output speed < Cut-out speed Cut in speed (cut-out wind speed refers to the maximum wind speed of wind turbine connected to the grid for power generation. If the wind speed exceeds this, the wind turbine will cut out of the grid, that is, the wind turbine will shut down and stop power generation) < Rated output speed < Cutting speed

% Check rated output power is greater than zero Check whether the rated output power is greater than zero

if ~(ratedOutputPower > 0)

error( 'Rated output power must be greater than zero.' );

end

% Check cut-in speed is less than rated output speed Cut in speed (for grid connected fans, it refers to the wind speed that meets the grid connection conditions, that is, the minimum wind speed that can generate power, and if it is lower than this wind speed, it will automatically stop) is less than the rated output speed (the fan reaches the minimum wind speed of the product's declared output power)

if ~(cutInSpeed < ratedOutputSpeed)

error( 'Cut-in speed must be less than rated output speed.' );

end

% Check rated output speed is less than cut-out speed

if ~(ratedOutputSpeed < cutOutSpeed)

error( 'Rated output speed must be less than cut-out speed.' );

end

if windSpeed < cutInSpeed

% Wind speed is less then cut-in speed, power output is zero

power = 0;

elseif windSpeed < ratedOutputSpeed

% Wind speed is greater than cut-in speed and less than rated output

% speed, power output follows linear characteristic from zero to rated

% power

cutInGradient = ( ratedOutputPower / ( ratedOutputSpeed - cutInSpeed ) );

power = cutInGradient * ( windSpeed - cutInSpeed );

elseif windSpeed < cutOutSpeed

% Wind speed is greater than rated output speed and less than cut-out

% speed, power output is limited to rated power

power = ratedOutputPower;

else

% Wind speed is greater than cut-out speed, power output is zero

power = 0;

end

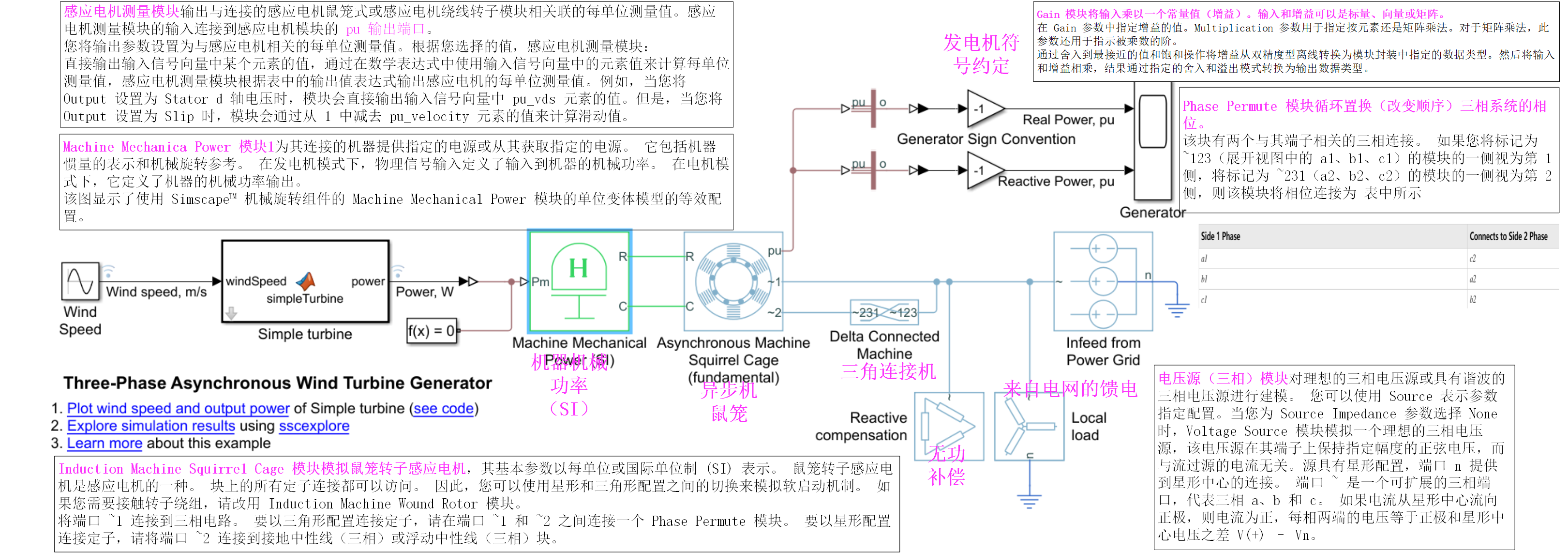

Solver Configuration: Simscape connected by ™ Each physical network represented by the block diagram requires solver setup information for simulation. The Solver Configuration module specifies the solver parameters that your model needs before starting the simulation. Each Simscape module diagram with different topology needs to be connected to exactly one Solver Configuration module.

https://lost-contact.mit.edu/afs/inf.ed.ac.uk/group/teaching/matlab-help/R2016b/physmod/simscape/ref/solverconfiguration.html

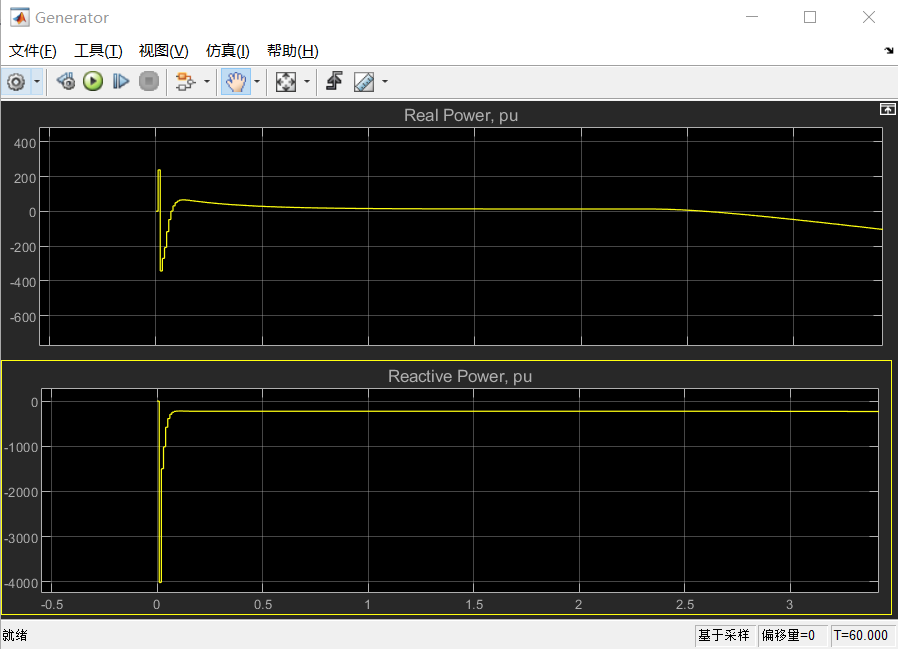

gain here is set to 1000. At the moment of starting, the motor has the maximum active power and the highest power factor! (the lighter the load, the lower the power factor) with the completion of startup, the active power gradually returns to the normal rated value, and the power factor gradually decreases from the highest to the rated value.

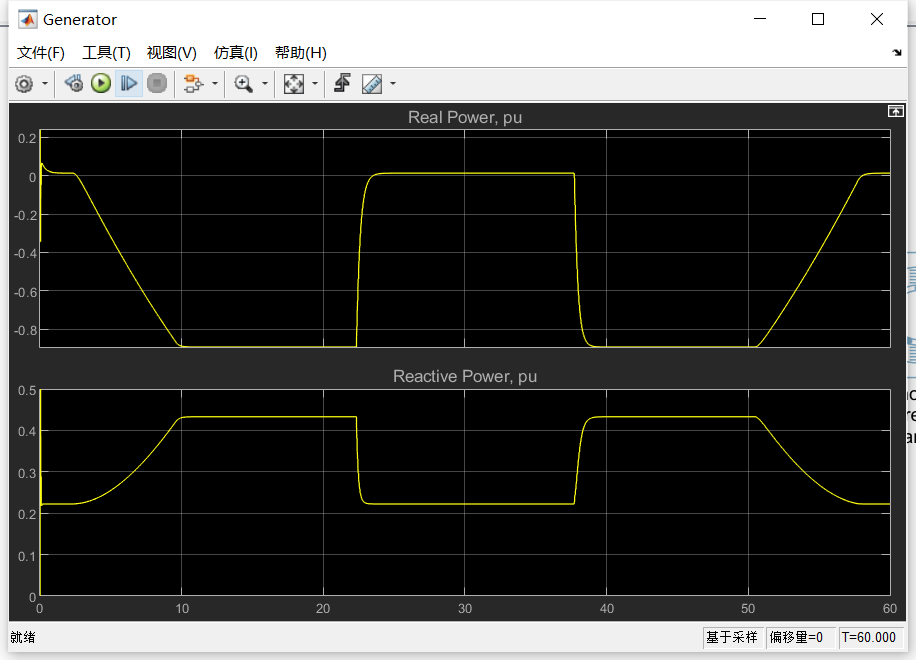

When Gain is set to 1, the display is as follows.

- The fan can convert the kinetic energy of the wind into mechanical energy and then into electrical energy. Wind is flowing air. Its kinetic energy is directly proportional to the product of air mass and wind speed square, and the air mass per unit area per unit time is directly proportional to the product of air density and custom. Therefore, the kinetic energy of wind per unit area per unit time is directly proportional to the product of air density and wind speed.

- Power coefficient is the ratio of the power generation of the fan to the kinetic energy of the wind before conversion. It is an index used to express the power generation efficiency. Generally, the power coefficient of small wind turbine is between 0.25 ~ 0.35. Since the energy will not be created out of nothing, the power coefficient value will not be greater than 1. In addition, the conversion energy of the fan must also meet the laws of fluid dynamics. According to the theoretical derivation of German physicist Bates in 1919, the power coefficient of the fan cannot be greater than 0.593. This theoretical limit also ignores the wind wake rotation and electromagnetic conversion loss, and the actual upper limit is even lower.

- When the rotating shaft of fan blade is perpendicular to the direction of wind, it is called vertical shaft fan. When the rotating shaft of fan blade is parallel to the direction of wind, it is called horizontal shaft fan. Because the wind direction near the surface is roughly parallel to the ground, the fan type can also be identified by whether the blade rotation axis is perpendicular or parallel to the ground. Generally speaking, the vertical shaft fan has slow speed and low noise, but the power coefficient is small, with a value of about 0.25 to 0.3. The horizontal shaft fan has fast speed and high noise, but the power coefficient is large, with a value of about 0.3 ~ 0.35.

- The starting speed is the minimum wind speed at which the fan starts to rotate from standstill and rotates continuously. Cut in speed is the minimum speed at which the fan starts to have power output to the rated load. Since the purpose of the fan is to generate electricity, the cut in speed is more important. Generally, the cutting speed of small fan is 3 ~ 6m / s. Because the kinetic energy of wind is proportional to the third power of wind speed, the energy converted by wind energy is very little at very low wind speed. However, most of the time, the wind is not large, so the startup of small fans is also an important feature.

- The rated wind speed is the minimum wind speed that enables the fan to reach the declared output power of the product. The larger the rated wind speed is, the smaller the sweeping diameter of the fan blade is, but the declared power generation capacity of the product can be output only under large wind conditions. Generally, the rated wind speed of small fans is set at 10 to 12 m / s. Since the output power of the wind turbine is directly proportional to the product of the power coefficient, air density, wind speed and the swept area of the blade, the larger the rated wind speed is, the smaller the swept diameter of the fan blade is. Under normal natural wind conditions, the occurrence probability of different wind speeds near the surface roughly conforms to the Weber distribution. The most common wind speed is about 5 ~ 7m / s. however, because the kinetic energy of the wind is directly proportional to the third power of the wind speed, the maximum probability of converted wind energy is about 10 ~ 12m / s. therefore, the rated wind speed of general small wind turbines is also set in this range.

- The main noise sources of the fan are high-frequency wind cutting noise from the blade and low-frequency buzzing noise from the fan. The horizontal shaft fan will also emit unique low-frequency wind noise, which is caused by the tower shadow effect when the blade is close to the tower, especially the downwind horizontal shaft fan. The blade wind cutting sound is caused by the vortex stripping pressure shock wave of the blade tail. The sound power of the vortex noise is directly proportional to the sixth power of the relative velocity of the wind and the blade. The special design of blades can reduce eddy current noise, but it may also change the flow condition and reduce power generation efficiency, which is one of the research and development priorities of wind turbine manufacturers. Xingao wind turbine is a vertical axis wind turbine, and the noise is relatively small. Therefore, we have developed vortex noise reduction methods. For the low-frequency noise of general generators, Xingao wind turbine has been equipped with suppression mechanism.

- The fan needs to pass the power performance test to determine that the output power of the fan can reach the declared power generation capacity of the product at the rated wind speed. Since the fan should be able to operate safely and normally for a certain life, it should pass the durability test and strength safety design review. Since the small fan is located close to the residential area, the noise value in the residential area shall be ensured to be less than that specified by laws and regulations through noise measurement. As the wind turbine power generation control system must ensure the safety of power use, it must pass the relevant certification of electric control system.

- Cut in wind speed refers to the wind speed that meets the grid connection conditions, that is, the lowest wind speed that can generate power. If the wind speed is lower than this, it will stop automatically. Cut out wind speed refers to the maximum wind speed of wind turbine connected to the grid for power generation. If the wind speed exceeds this, the wind turbine will cut out of the grid, that is, the wind turbine will shut down and stop power generation. The cut in speed is related to the aerodynamic performance of the blade. When this wind speed is reached, the generator can generate electricity continuously and stably. The cut-out wind speed is not only related to the blade, but also related to the unit load. If the cut-out wind speed is not reached, there may be the risk of tower collapse, impeller flying and other accidents. The power consumed during startup is generally less than the power generation when the cut-in wind speed is reached. Fan is related to the transmission and distribution energy consumption of the system and is a very key part of building energy conservation. According to many years of fan testing by the national air conditioning equipment quality supervision and inspection center, many fans have problems under rated working conditions. Therefore, it is necessary to produce and manufacture fans in strict accordance with the requirements of product standards.

At the beginning of the operation of the fan, the vibration of the bearing is very small, but with the extension of the operation time, the dust in the fan will adhere to the impeller unevenly, gradually destroy the dynamic balance of the fan and gradually increase the bearing vibration. Once the vibration reaches the maximum allowable value of 11mm/s (the maximum allowable value expressed by the amplitude value is as follows), the fan must be shut down for repair (remove the dust accumulation and redo the dynamic balance). Because it is very dangerous at this time, the user must not use it forcibly. When the fan vibration approaches the dangerous value, the vibration measuring instrument will give an alarm.