I haven't found anything useful for a long time, so I transplanted the HAL library myself. Now share it

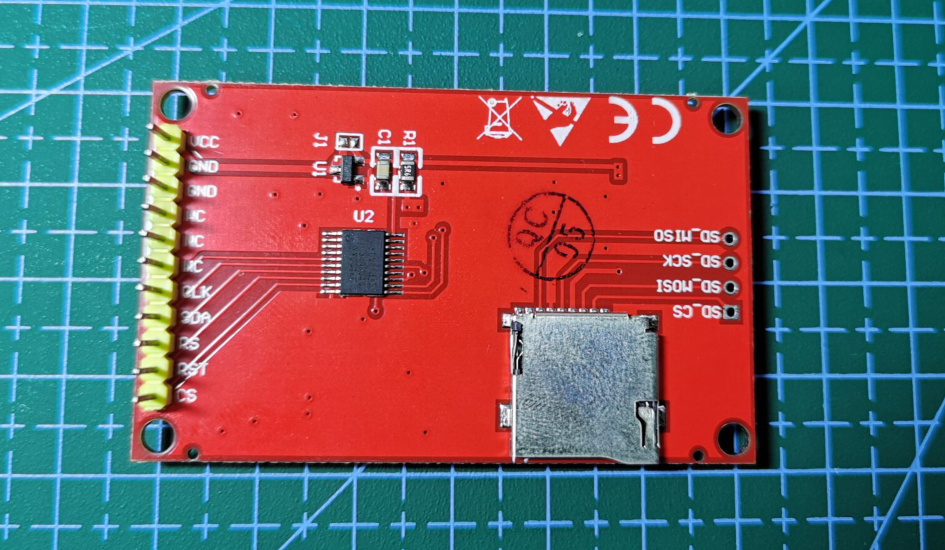

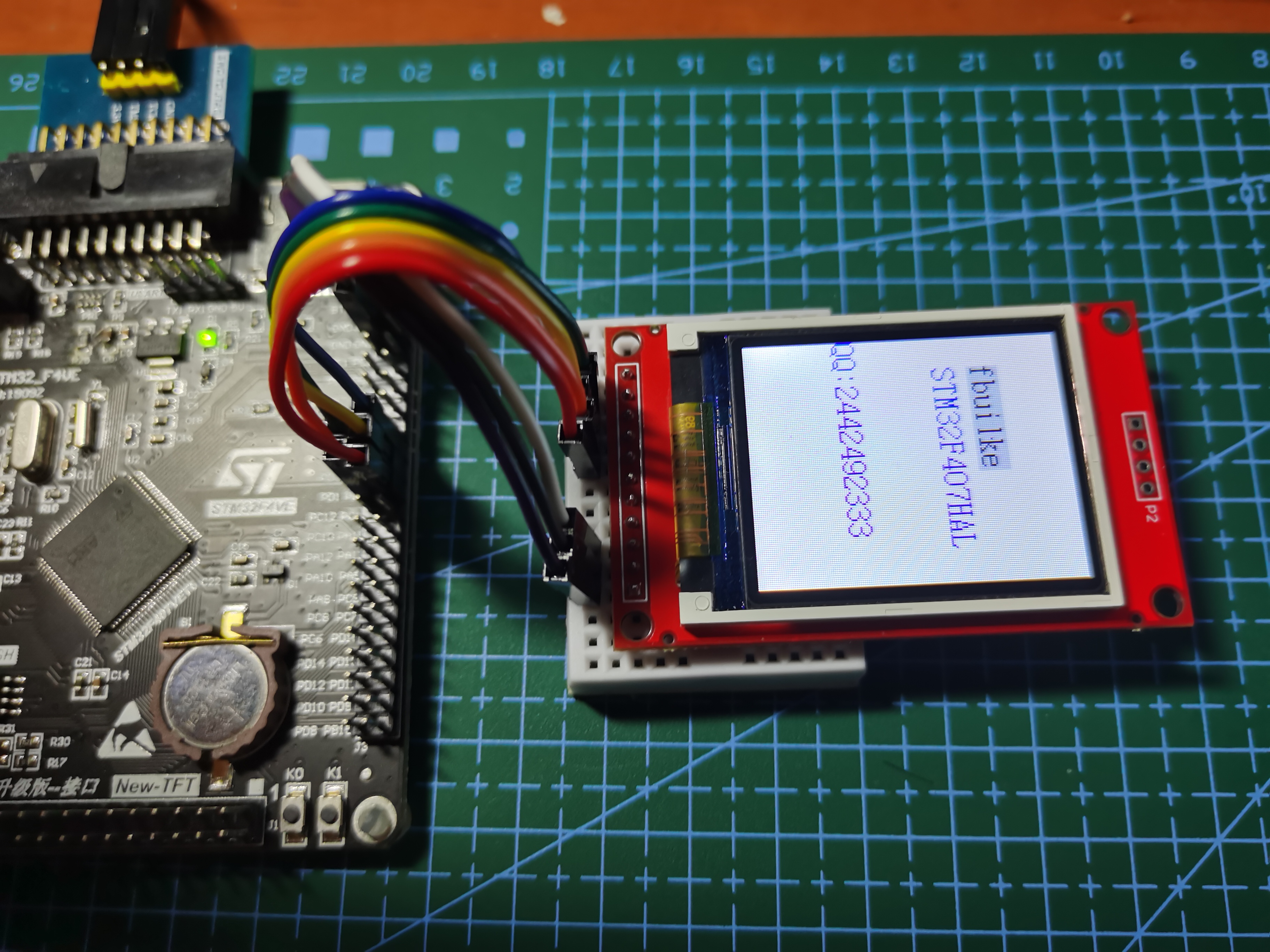

The price of the screen has increased a lot recently, In order to be cheap, I bought a 1.8-inch touch-free TFT (ST7735) screen at a treasure for 23. After buying it, I found that it was slightly different from others. I didn't see relevant references on the Internet. There were only a few routines given by the store, but the pin definitions in the routines were different from those I got. I couldn't control the backlight. What I got was the following screen

It can be seen that there are only five effective pins CLK, SDA (MOSI), RS, RST and CS, and there is less to control the backlight LED pin. However, this is not a big problem. Because other functions of the project are developed using HAL library, we can only change the driver routine of STM32F103 firmware library and transplant it to STM32F407HAL library.

catalogue

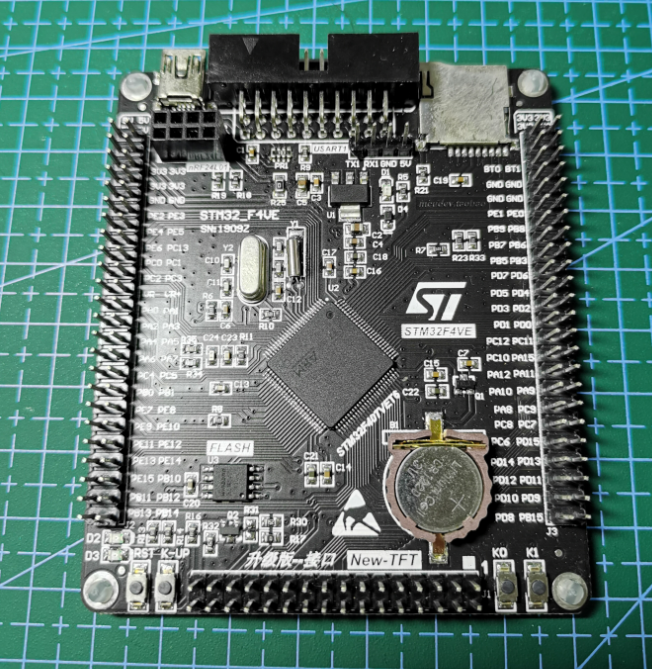

hardware platform

The hardware platform used this time is STM32F407VET6 core board

The software uses keil 5 35 and STM32CubeMX

Wiring mode

- VCC # 3.3V (5V is easy to burn the screen)

- GND GND

- GND GND

- NC = suspended

- NC = suspended

- NC = suspended

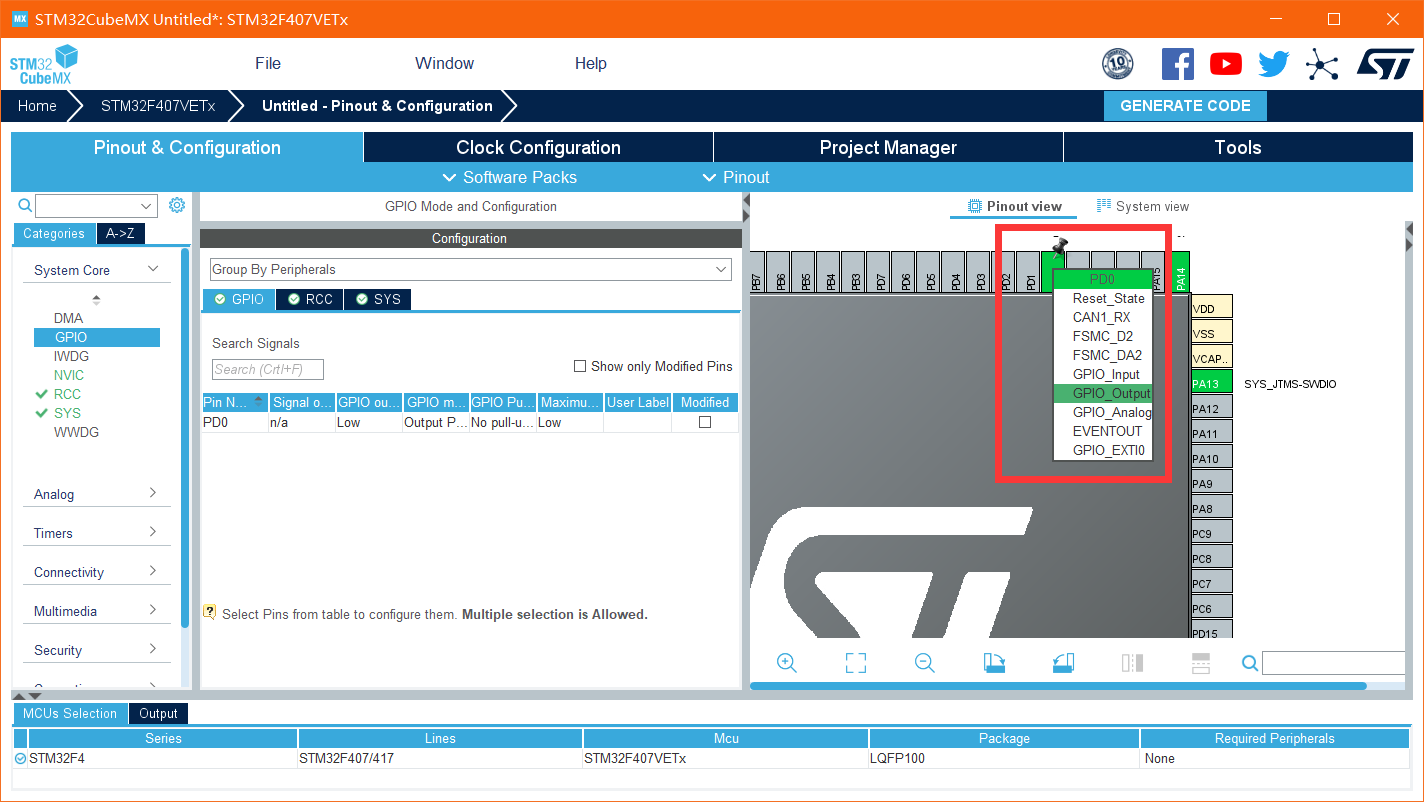

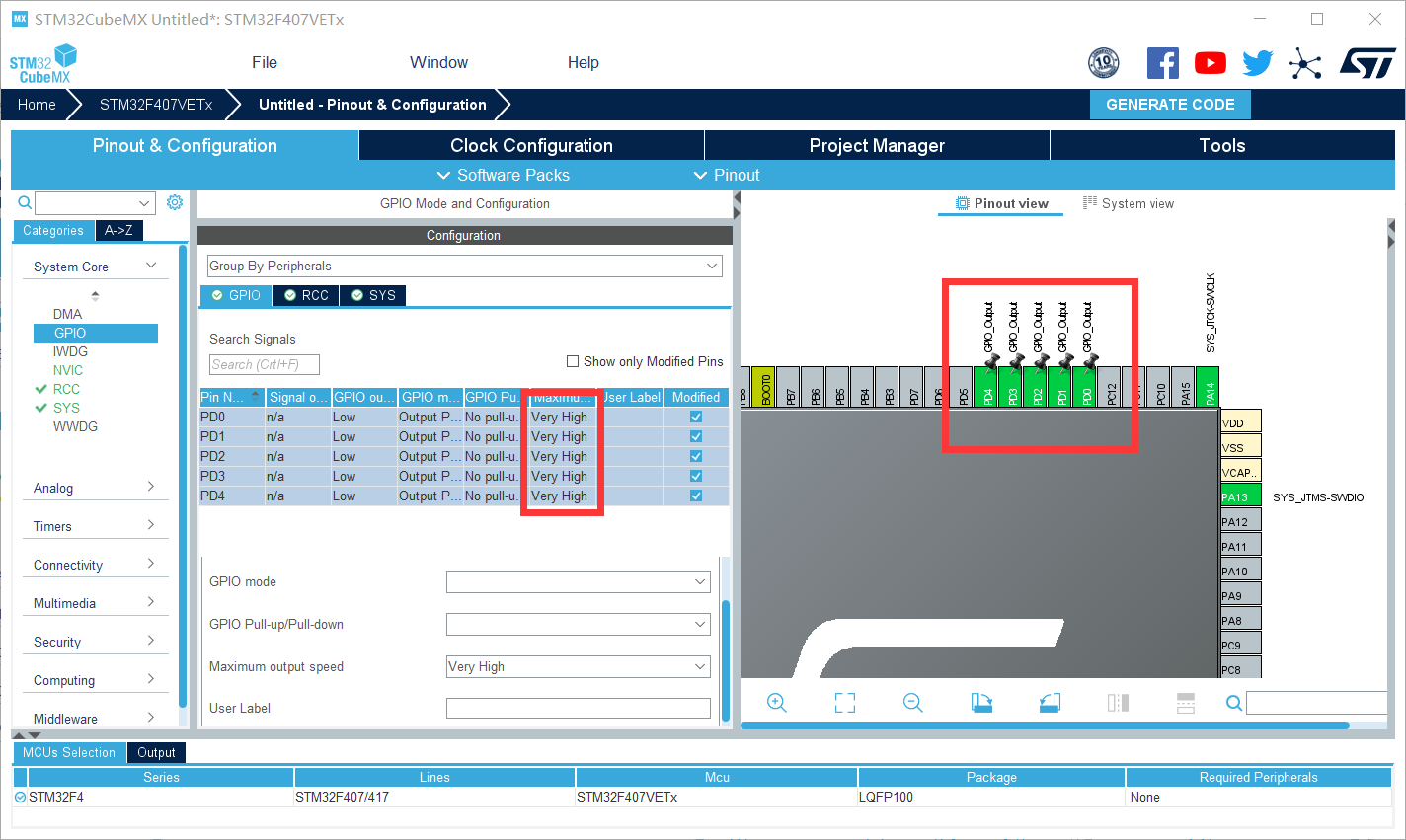

- CLK PD0

- SDA/MOSI PD1

- RS/DC PD2

- RST/RES PD3

- CS/CE PD4

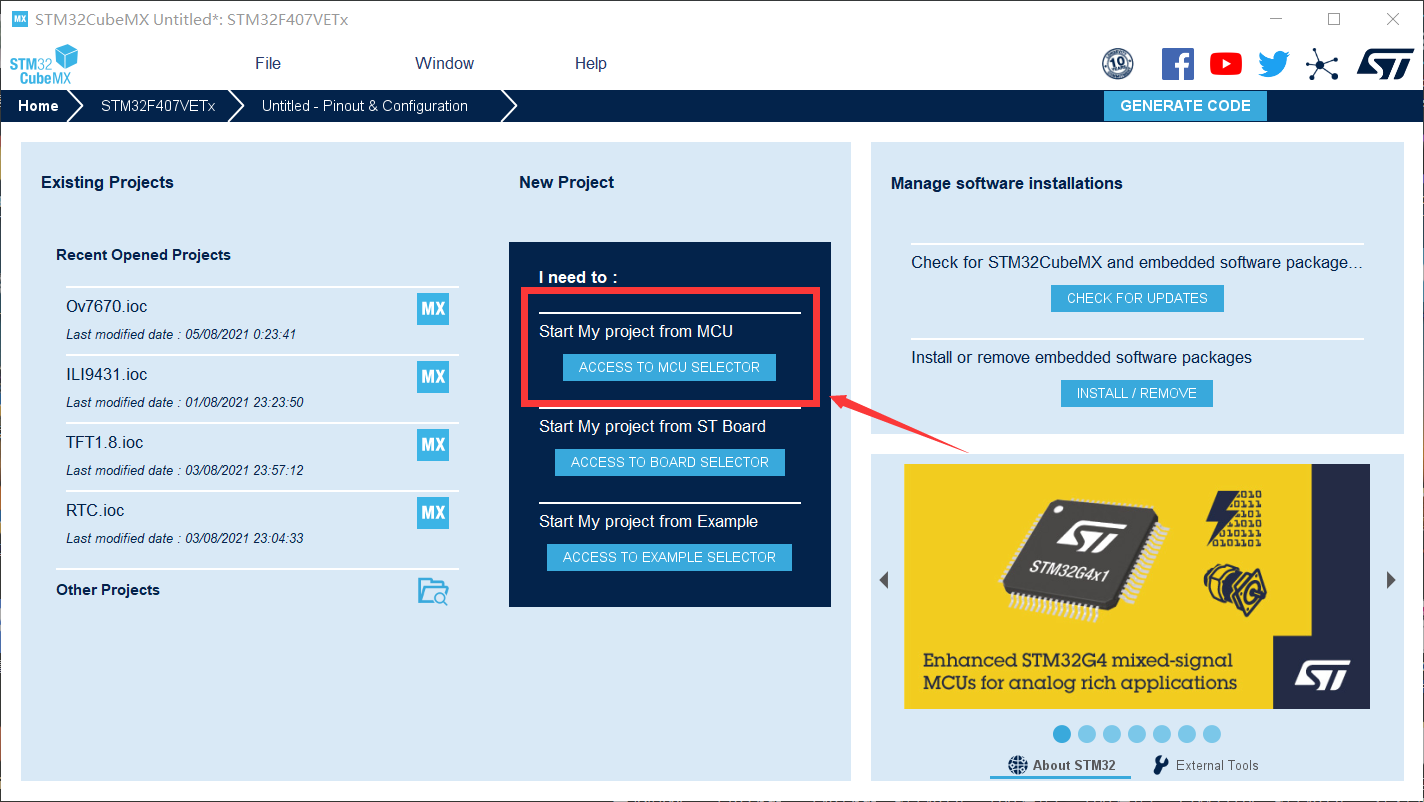

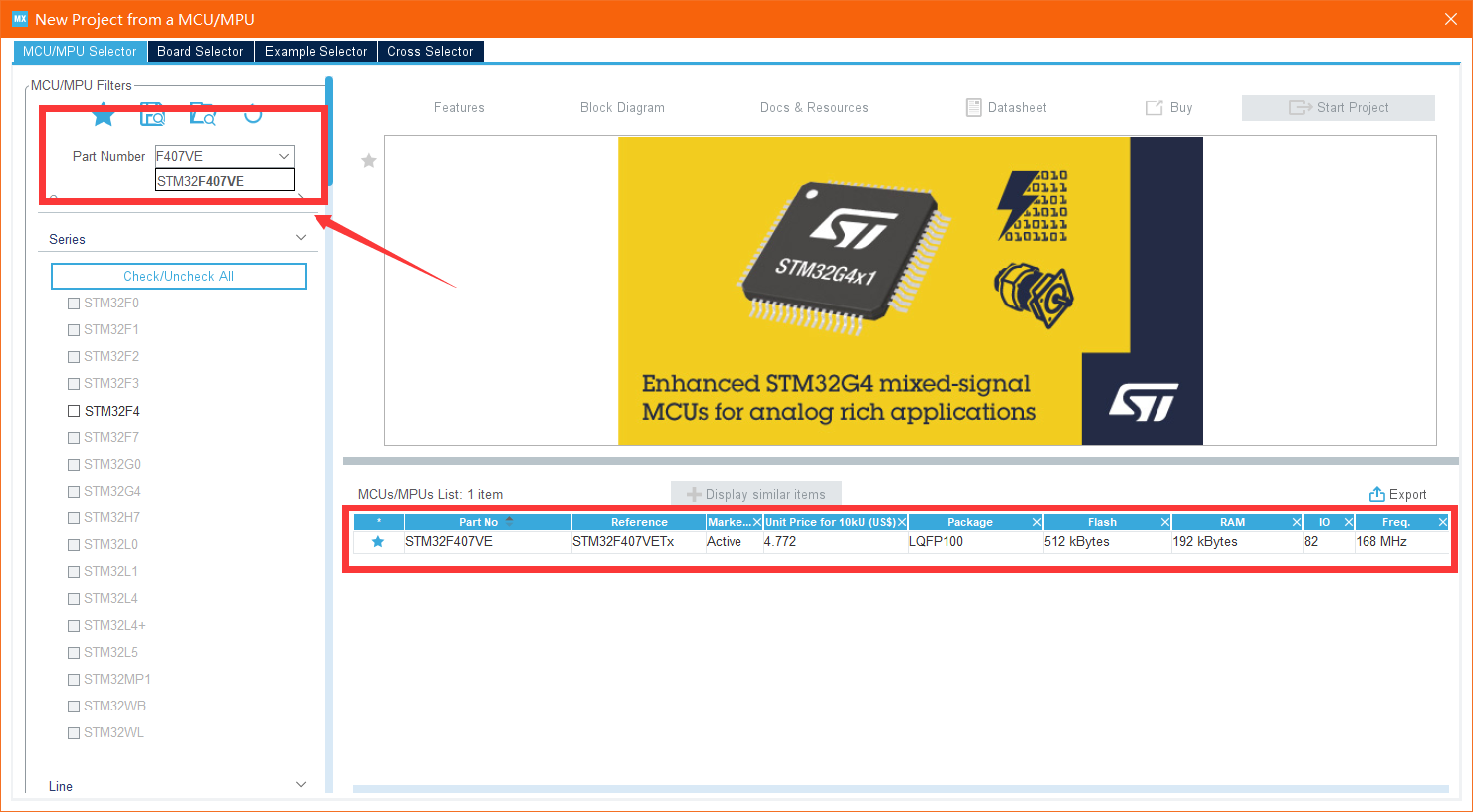

STM32CubeMX configuration

Step 1: select the chip:

Then find the chip model on your development board (I recommend that you click which star to collect the chip model on your development board. Next time, you can directly click the favorite next to the search box)

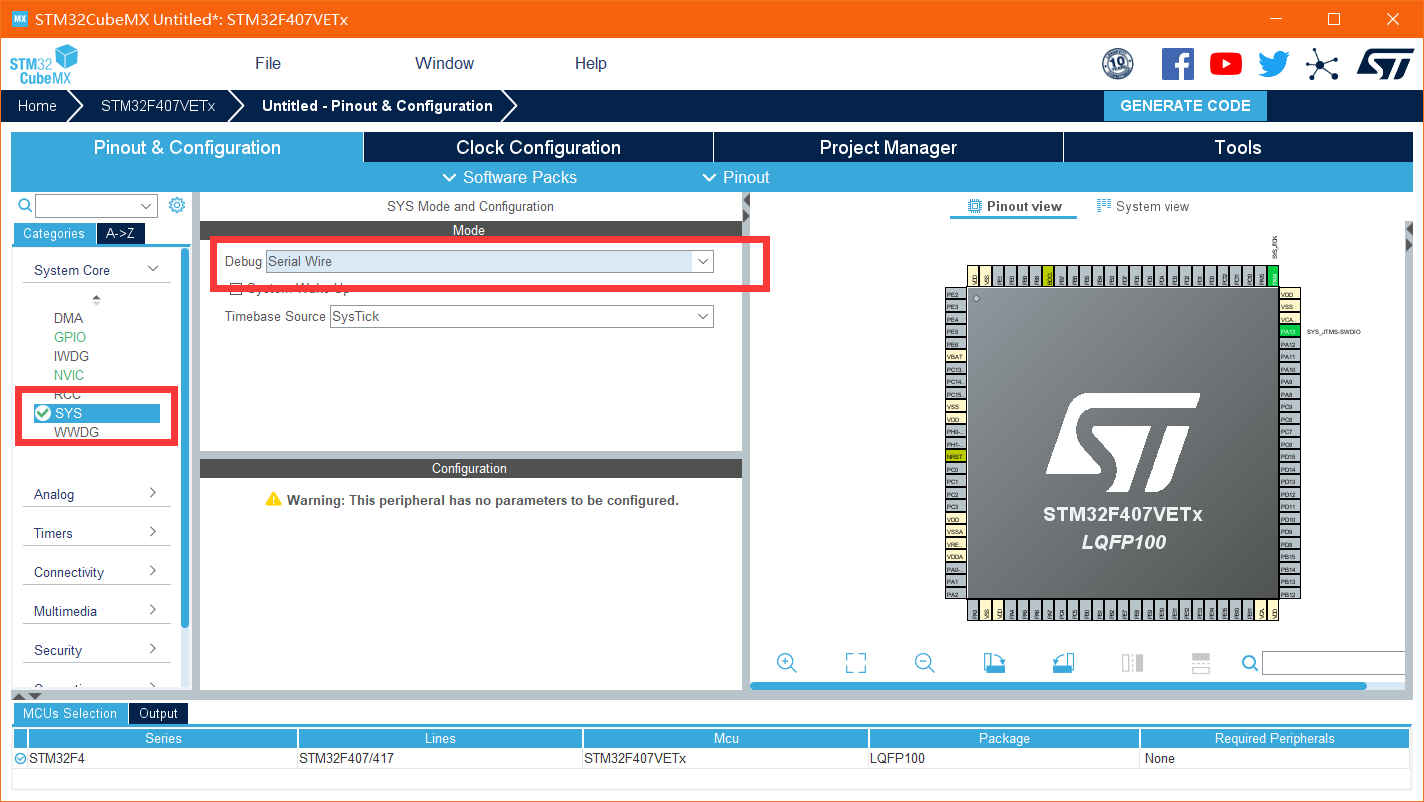

Step 2 start debugging (prevent the chip from locking) and configure the IO port

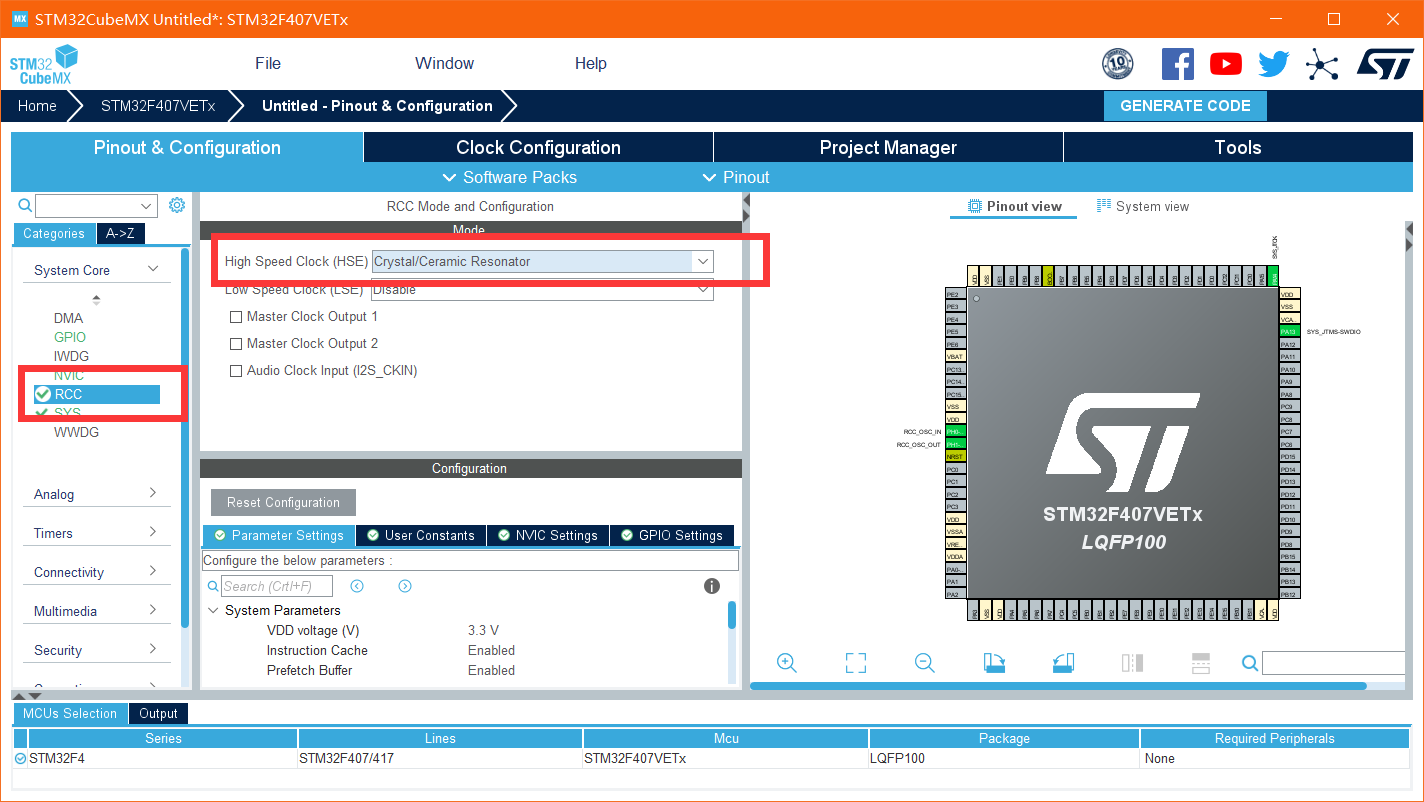

Select use external high speed clock

Configure IO

The following four configurations are the same: no pull-down, push-pull output, and turn the IO rate to the highest very high (to make the screen refresh faster)

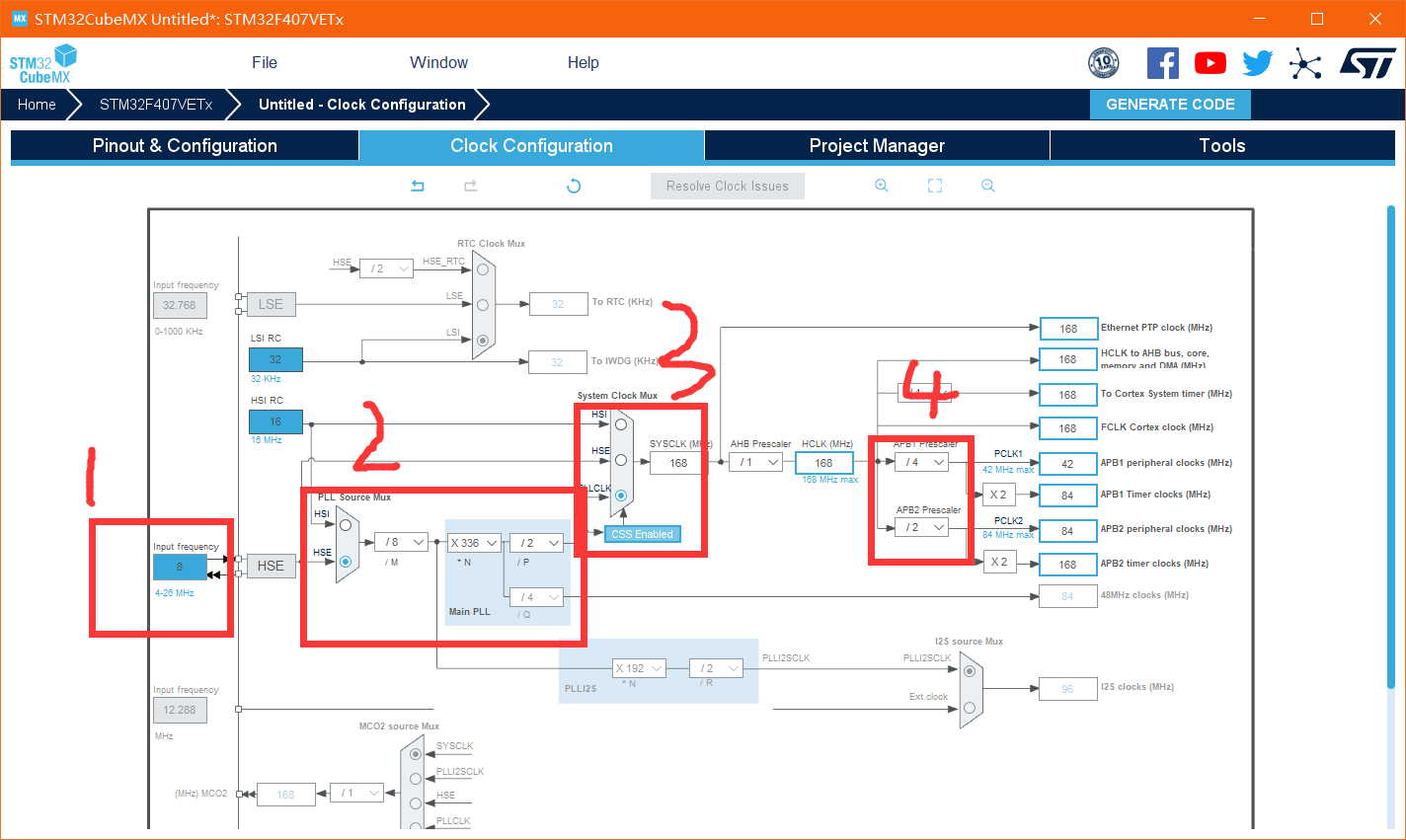

Step 3 configure the clock

Because the board is equipped with 8M crystal oscillator, it needs to be changed. cubemx defaults to 25M crystal oscillator

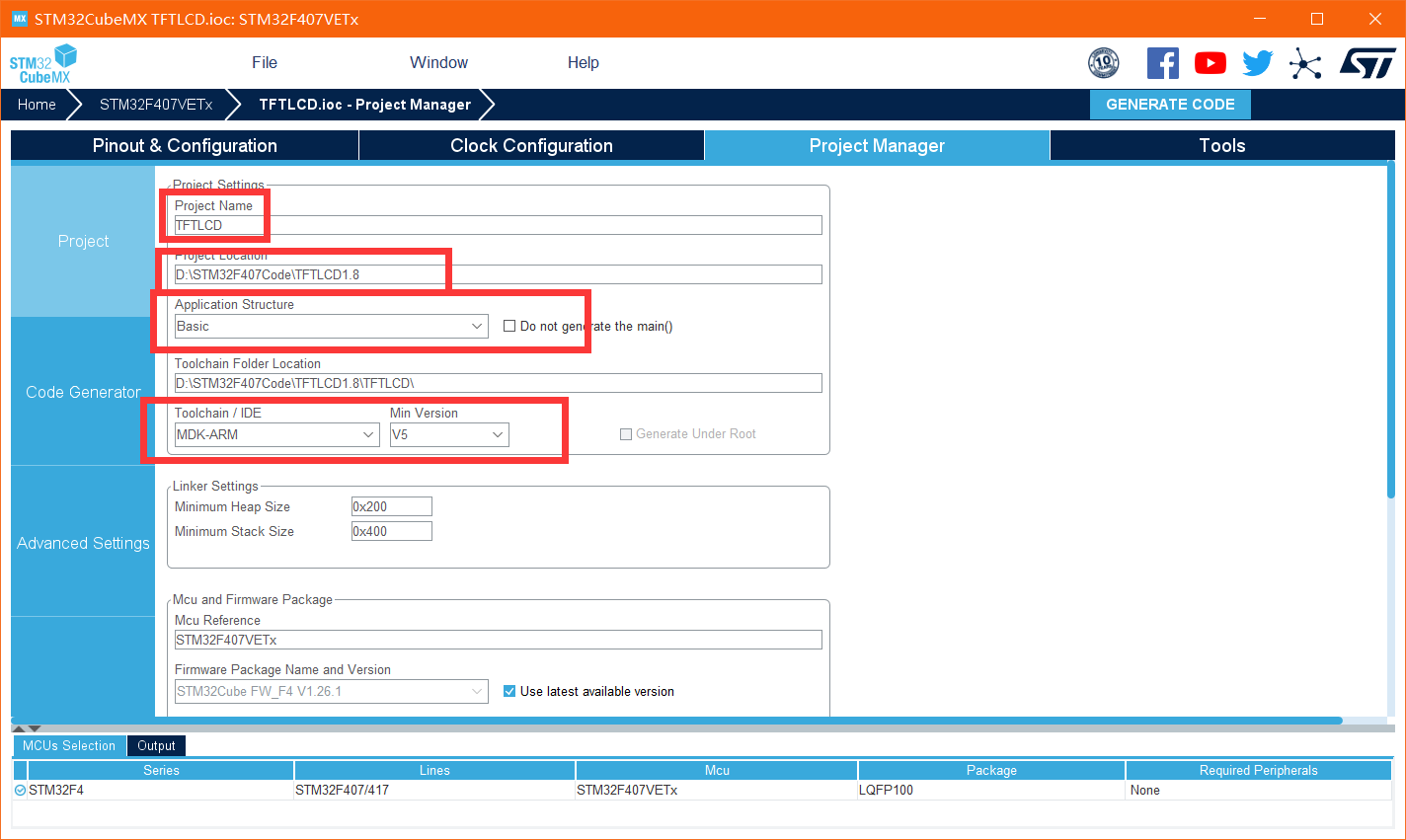

Step 4 set project configuration

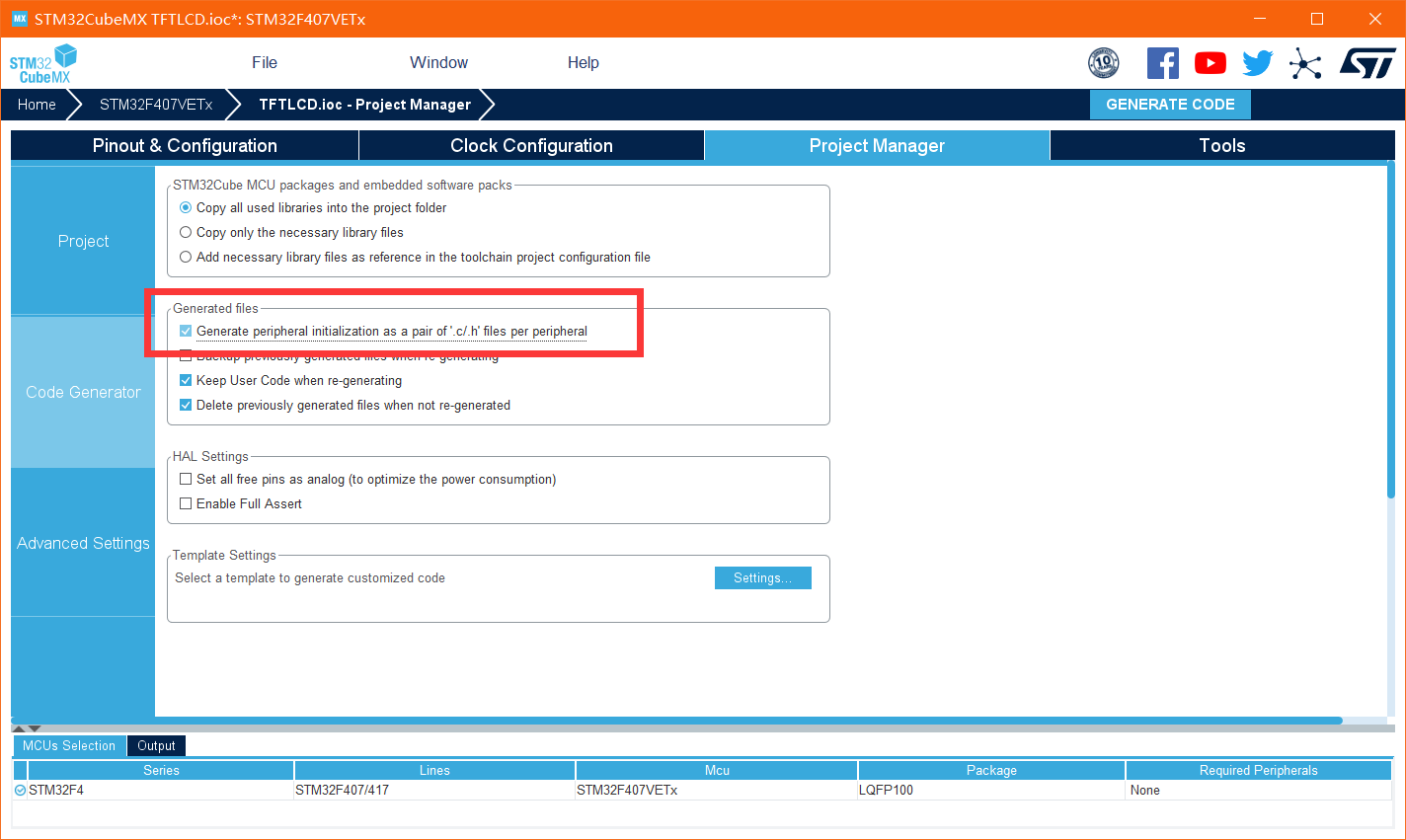

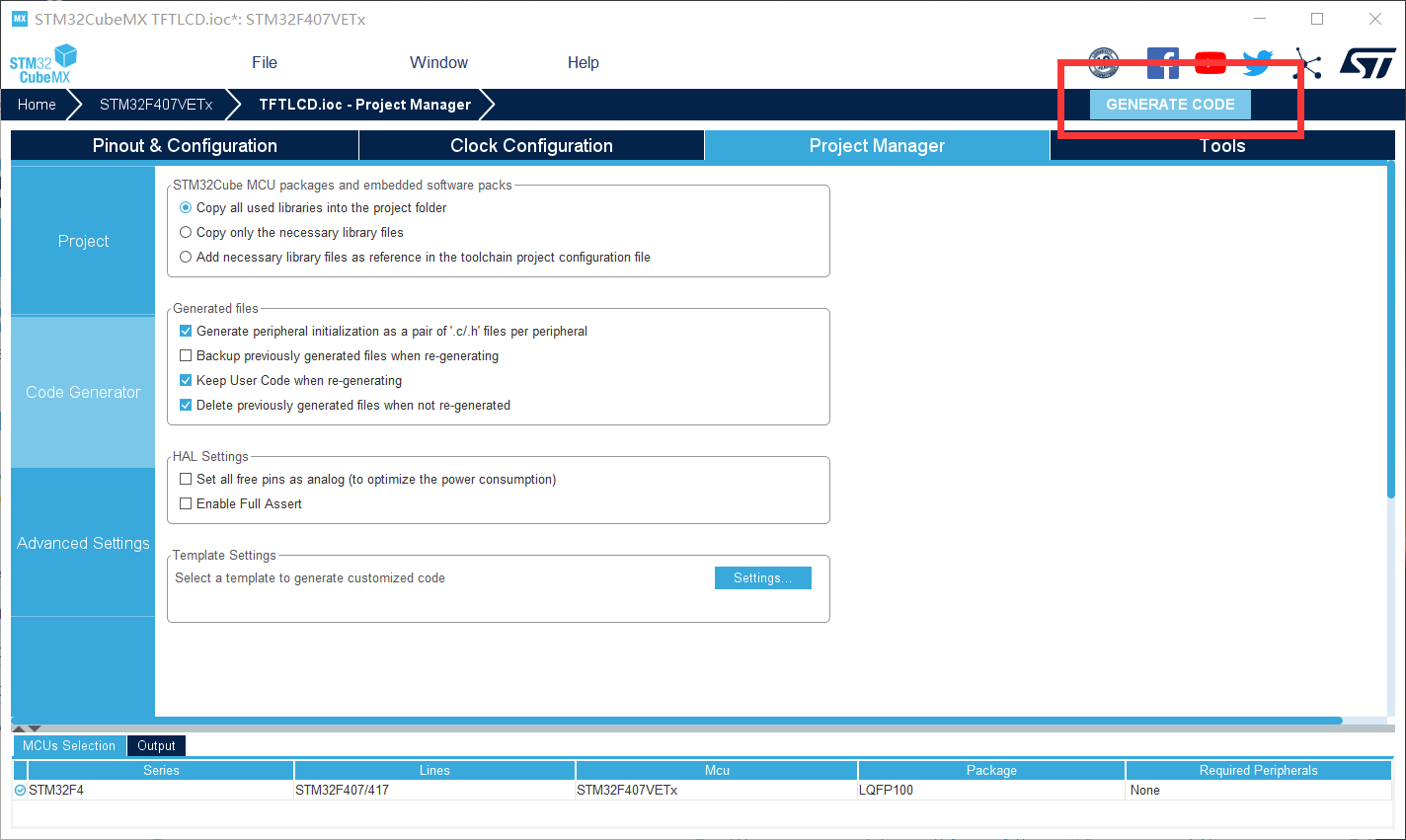

The last step is to generate the code

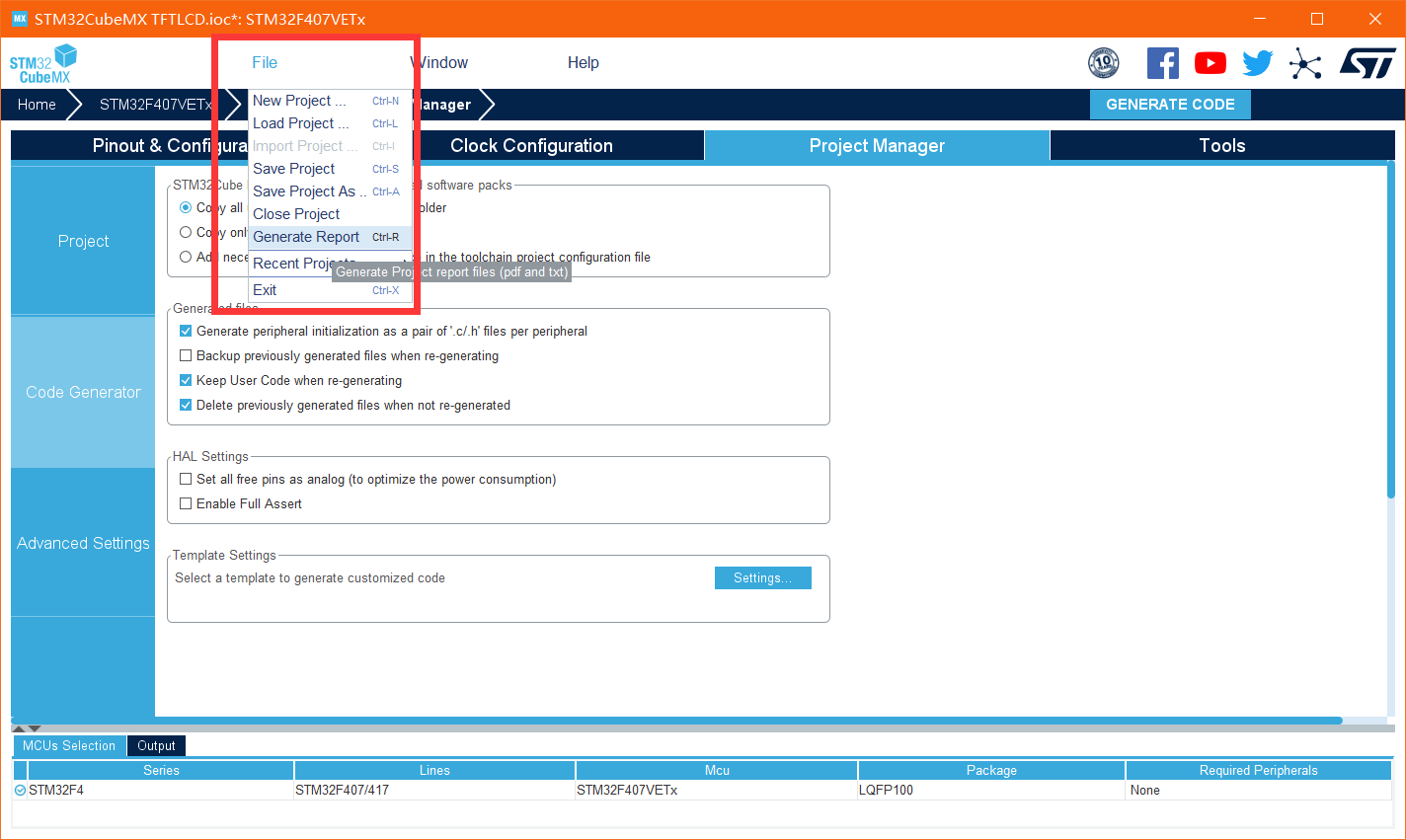

Mr. Cheng reports and gets an ioc file of cubemx. You can continue to configure it later

Then click the generate code in the upper right corner (the path of the generated code cannot exist in Chinese, otherwise the generated code will fail)

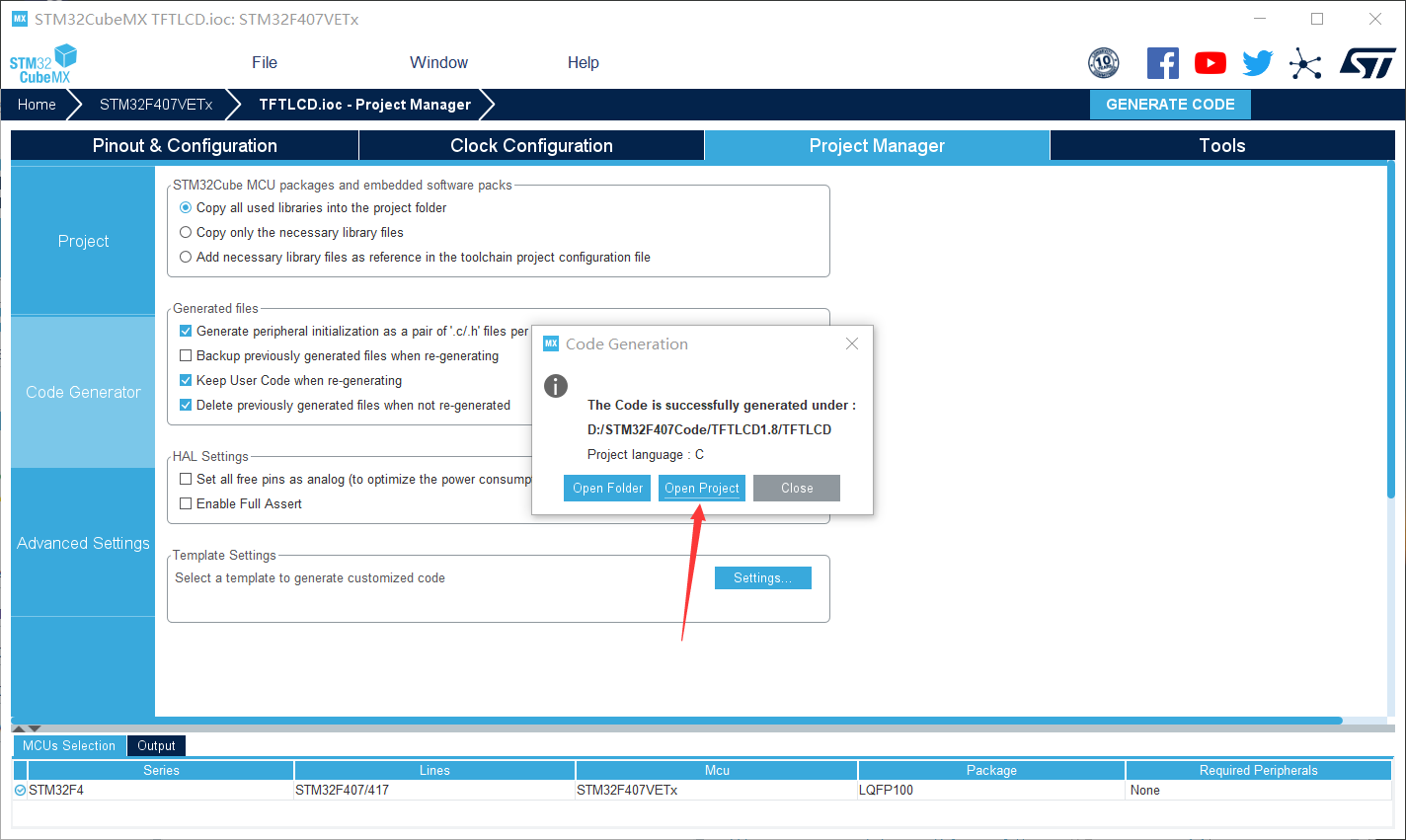

After successful generation, directly click to open the project

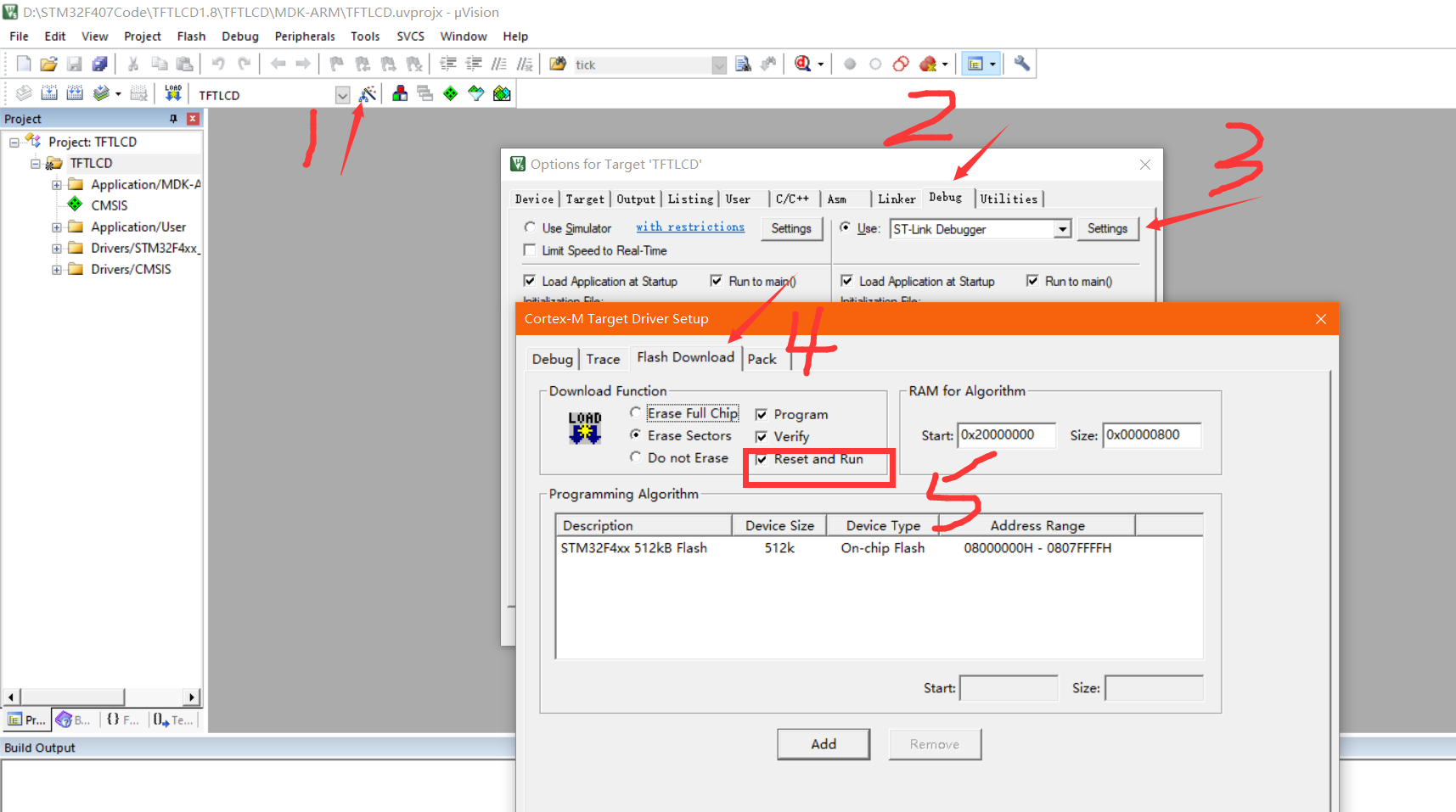

Open the project and configure it for download

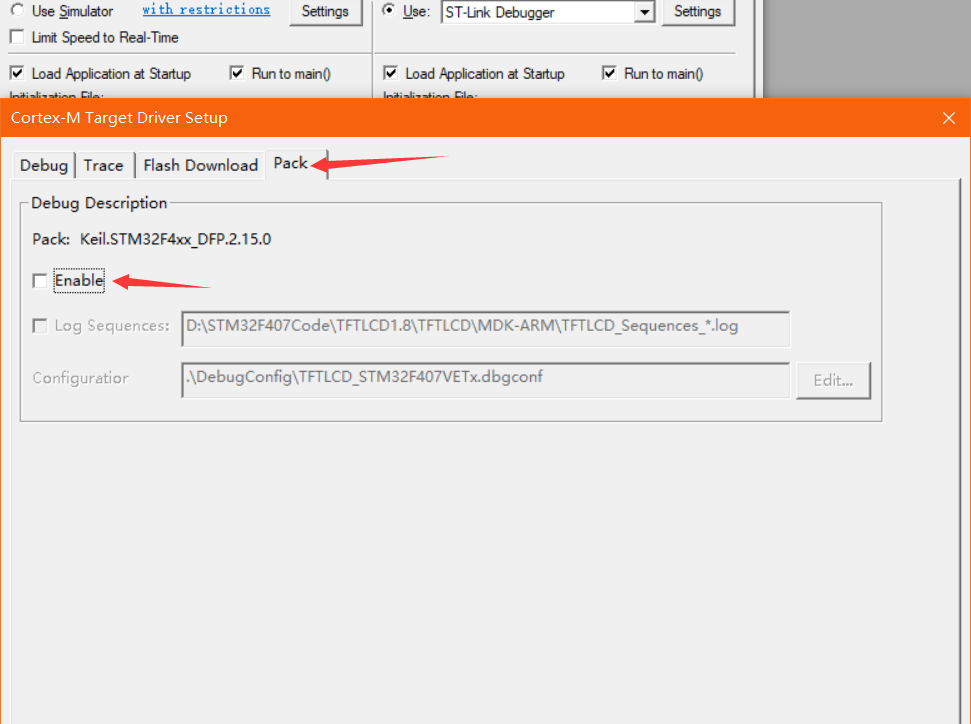

Then select pack to cancel (to prevent the operation from being reset after downloading)

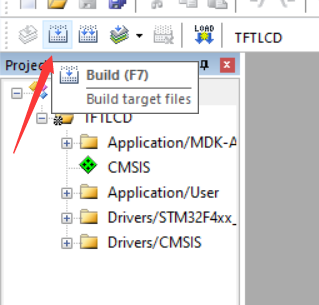

After completion, compile the project first

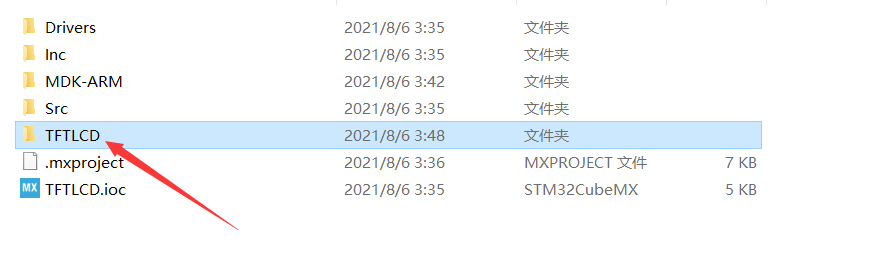

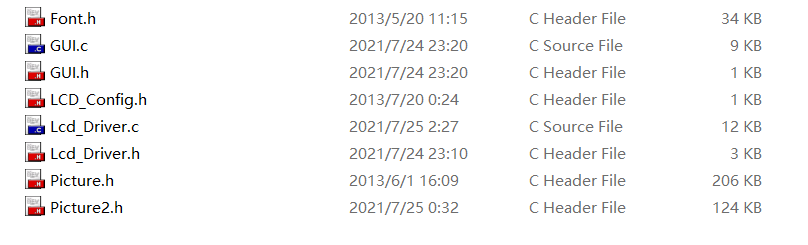

Then go back to the project directory and create a file to install the migrated program

Open the program that contains the transplant

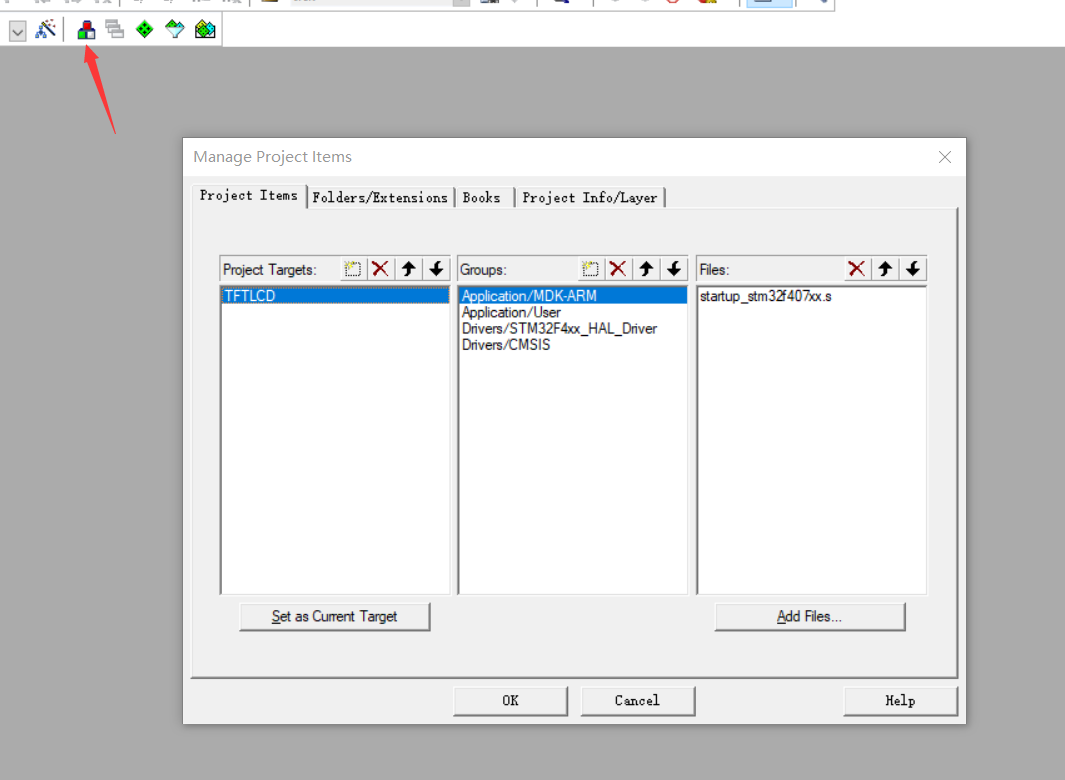

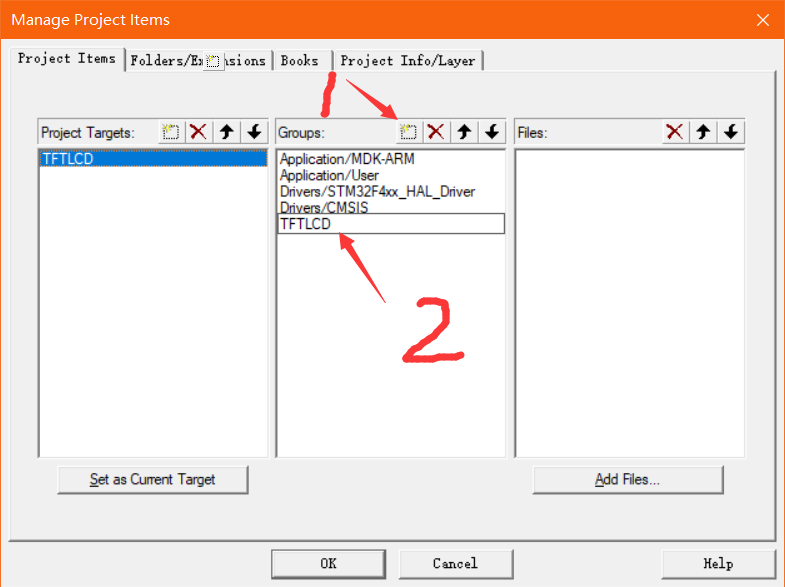

Go back to keil and order this

Then create a new one

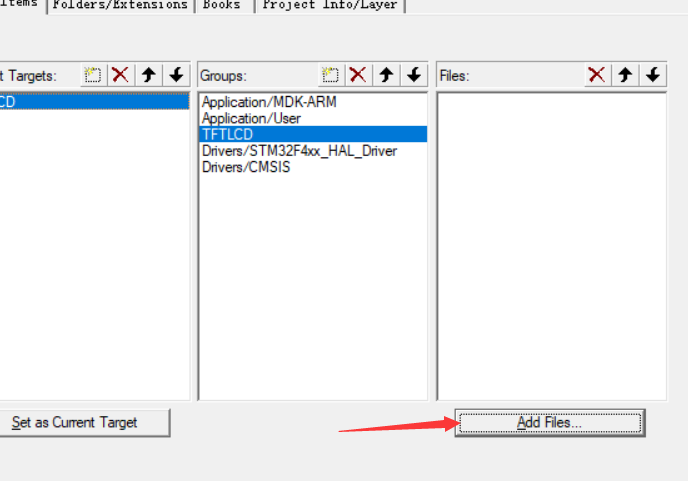

Select the new key to add files to it

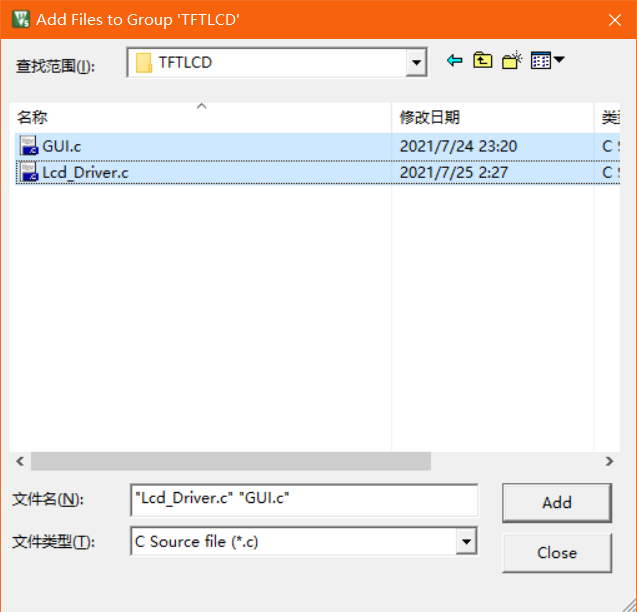

Find the C file just migrated, add it, and click ok

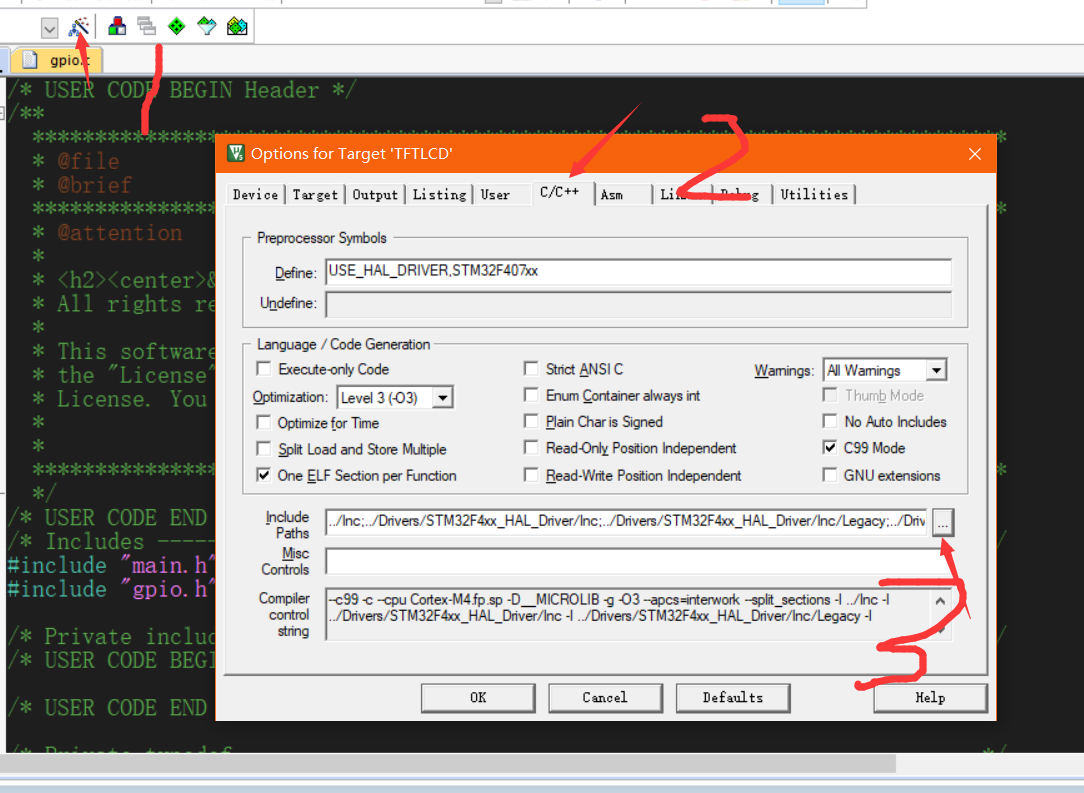

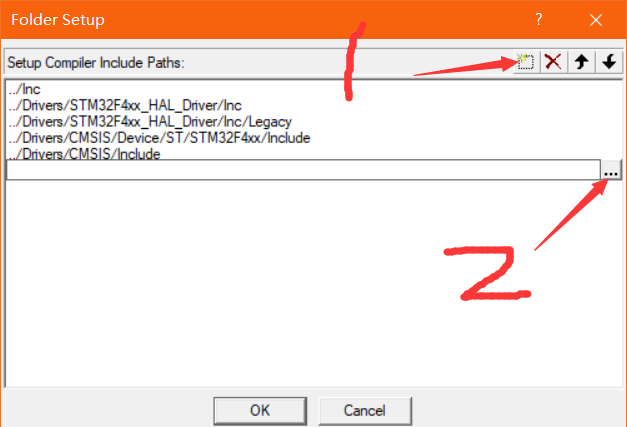

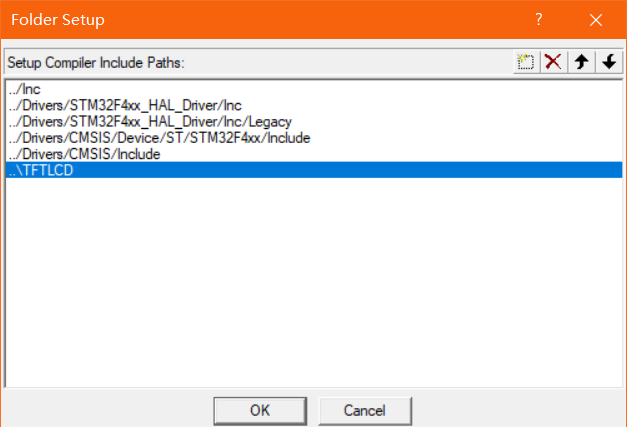

Then add the header file directory

Then create a new path and click the sequence number next to it to select the header file path

Then click ok

Here, most of the migration process has been completed, and the next step is to change the code

Code part

Lcd_ Driver. H (partial code)

#include "stm32f4xx_hal.h" #include "stm32f407xx.h" #define RED 0xf800 #define GREEN 0x07e0 #define BLUE 0x001f #define WHITE 0xffff #define BLACK 0x0000 #define YELLOW 0xFFE0 #define GRAY0 0xEF7D // Gray 0 3165 00110 001011 00101 #define GRAY1 0x8410 // Grey 1 00000 000000 00000 #define GRAY2 0x4208 // Grey 2 1111111111011111 #define LCD_CTRL GPIOD // Define TFT data port #define LCD_RS GPIO_PIN_2 //TFT --RS/DC #define LCD_CS GPIO_PIN_4 //TFT --CS/CE #define LCD_RST GPIO_PIN_3 //TFT --RST #define LCD_SCL GPIO_PIN_0 //TFT --SCL/SCK #define LCD_SDA GPIO_PIN_1 //TFT --SDA/DIN #define LCD_CS_SET LCD_CTRL->BSRR=LCD_CS #define LCD_RS_SET LCD_CTRL->BSRR=LCD_RS #define LCD_SDA_SET LCD_CTRL->BSRR=LCD_SDA #define LCD_SCL_SET LCD_CTRL->BSRR=LCD_SCL #define LCD_RST_SET LCD_CTRL->BSRR=LCD_RST #define LCD_LED_SET LCD_CTRL->BSRR=LCD_LED void LCD_GPIO_Init(void); void Lcd_WriteIndex(uint8_t Index); void Lcd_WriteData(uint8_t Data); void Lcd_WriteReg(uint8_t Index,uint8_t Data); uint16_t Lcd_ReadReg(uint8_t LCD_Reg); void Lcd_Reset(void); void Lcd_Init(); void Lcd_Clear(uint16_t Color); void Lcd_SetXY(uint16_t x,uint16_t y); void Gui_DrawPoint(uint16_t x,uint16_t y,uint16_t Data); unsigned int Lcd_ReadPoint(uint16_t x,uint16_t y);

Lcd_ Driver. C (partial code)

/******************************************************************************

The interface is defined in LCD_ Driver. Within H

#define LCD_CTRL GPIOD

#define LCD_SCL GPIO_Pin_0 //SCL/SCK

#define LCD_SDA GPIO_Pin_1 //SDA/DIN

#define LCD_RS GPIO_Pin_2 //RS/DC

#define LCD_RST GPIO_Pin_3 //RST

#define LCD_CS GPIO_Pin_4 //CS/CE

*******************************************************************************/

void LCD_GPIO_Init(void)

{

GPIO_InitTypeDef GPIO_InitStruct = {0};

__HAL_RCC_GPIOD_CLK_ENABLE();

GPIO_InitStruct.Pin = GPIO_PIN_0|GPIO_PIN_1|GPIO_PIN_2|GPIO_PIN_3

|GPIO_PIN_4;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_PP;

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_VERY_HIGH;

HAL_GPIO_Init(GPIOD, &GPIO_InitStruct);

}

/****************************************************************************

* Name: Lcd_WriteIndex(uint8_t Index)

* Function: write ST7735 controller register address

* Entry parameter: Index register address

* Outlet parameters: None

* Note: select the controller and internal function before calling

* Calling method: Lcd_WriteIndex(0xB1);

****************************************************************************/

void Lcd_WriteIndex(uint8_t Index)

{

uint8_t i=0;

//SPI write command timing start

LCD_CS_CLR;

LCD_RS_CLR;

for(i=8;i>0;i--)

{

if(Index&0x80){

LCD_SDA_SET; }//output data

else

LCD_SDA_CLR;

LCD_SCL_CLR;

LCD_SCL_SET;

Index<<=1;

}

LCD_CS_SET;

}

/****************************************************************************

* Name: void Lcd_WriteData(uint8_t Data)

* Function: write ST7735 register data

* Entry parameter: Data register Data

* Outlet parameters: None

* Note: write data to the specified address of the controller. Before calling, write the register address and internal function

* Calling method: Lcd_WriteData(0x01);

****************************************************************************/

void Lcd_WriteData(uint8_t Data)

{

uint8_t i=0;

LCD_CS_CLR;

LCD_RS_SET;

for(i=8;i>0;i--)

{

if(Data&0x80) {

LCD_SDA_SET;} //output data

else LCD_SDA_CLR;

LCD_SCL_CLR;

LCD_SCL_SET;

Data<<=1;

}

LCD_CS_SET;

}

/*************************************************

Function name: Lcd_WriteReg

Function: write register

Entry parameters: Index,Data

Return value: None

*************************************************/

void Lcd_WriteReg(uint8_t Index,uint8_t Data)

{

Lcd_WriteIndex(Index);

Lcd_WriteData(Data);

}

/*************************************************

Function name: Lcd_Reset

Function: reset LCD

Entry parameters: None

Return value: None

*************************************************/

void Lcd_Reset(void)

{

LCD_RST_CLR;

HAL_Delay(100);

LCD_RST_SET;

HAL_Delay(50);

}

/*************************************************

Function name: Lcd_SetRegion

Function: set lcd display area, write some data in this area and wrap automatically

Entry parameter: x_start start, y_start start, x_end,y_end end

Return value: None

*************************************************/

void Lcd_SetRegion(uint16_t x_start,uint16_t y_start,uint16_t x_end,uint16_t y_end)

{

Lcd_WriteIndex(0x2a);

Lcd_WriteData(0x00);

Lcd_WriteData(x_start);

Lcd_WriteData(0x00);

Lcd_WriteData(x_end);

Lcd_WriteIndex(0x2b);

Lcd_WriteData(0x00);

Lcd_WriteData(y_start);

Lcd_WriteData(0x00);

Lcd_WriteData(y_end);

Lcd_WriteIndex(0x2c);

}

/*************************************************

Function name: Lcd_SetXY

Function: set lcd display starting point

Entry parameters: xy coordinates

Return value: None

*************************************************/

void Lcd_SetXY(uint16_t x,uint16_t y)

{

Lcd_SetRegion(x,y,x,y);

}

/*************************************************

Function name: Gui_DrawPoint

Function: draw a point

Entry parameters: x,y,Data

Return value: None

*************************************************/

void Gui_DrawPoint(uint16_t x,uint16_t y,uint16_t Data)

{

Lcd_SetRegion(x,y,x+1,y+1);

Lcd_WriteData(Data>>8);

Lcd_WriteData(Data);

}

/*****************************************

Function name: Lcd_ReadPoint

Function function: read the color of a TFT point

Exit parameter: Data point color value

******************************************/

unsigned int Lcd_ReadPoint(uint16_t x,uint16_t y)

{

unsigned int Data;

Lcd_SetXY(x,y);

//Lcd_ReadData();// Discard useless bytes

//Data=Lcd_ReadData();

Lcd_WriteData(Data);

return Data;

}

/*************************************************

Function name: Lcd_Clear

Function: full screen clearing function

Entry parameters: fill Color

Return value: None

*************************************************/

void Lcd_Clear(uint16_t Color)

{

unsigned int i,m;

Lcd_SetRegion(0,0,X_MAX_PIXEL-1,Y_MAX_PIXEL-1);

Lcd_WriteIndex(0x2C);

for(i=0;i<128;i++)

for(m=0;m<160;m++)

{

Lcd_WriteData(Color>>8);

Lcd_WriteData(Color);

}

}

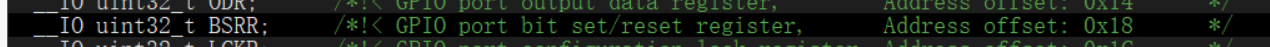

It is worth noting that the BSRR set register and BRR reset register of F103 have become

If there is a flower screen on the edge of the screen, it means that the pixels are not filled enough. Modify Lcd_Driver.c and GUI C internal circulation volume

The whole screen graphic display function is actually to light up the corresponding coordinate pixels and display the color

Well, all the work has been completed here. Burn and see the effect.

Operation effect

It can be seen that the screen refresh rate is quite fast, thanks to the increase of STM32F407IO rate

F103 is relatively slow

Mold taking part

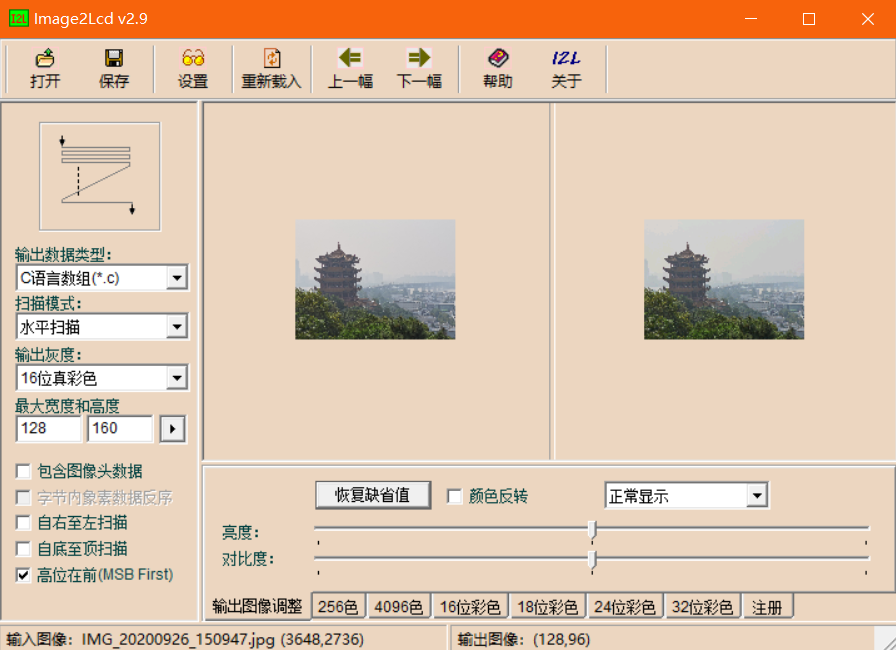

Image modeling

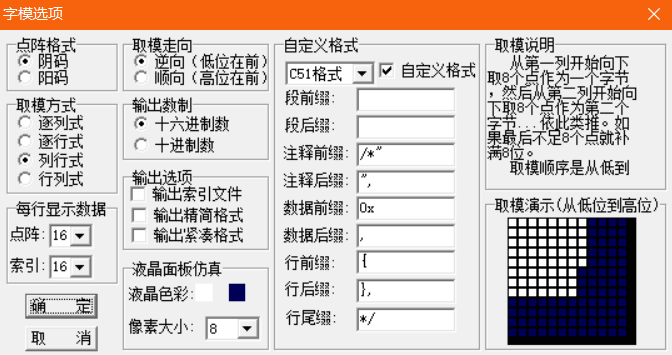

Text template

Of course, STM32F103C8T6HAL library is also transplanted. If necessary, leave a comment.

I've uploaded the code. Give me some points if you have points. Leave an email for comments if you don't have points